REMAN & OVERHAUL SOLUTIONS

As good as new

Your mtu equipment is built to last thanks to mtu’s legendary high engineering standards and unwavering commitment to service and support. And after a long and productive life, mtu provides options to help you and your equipment go even further.

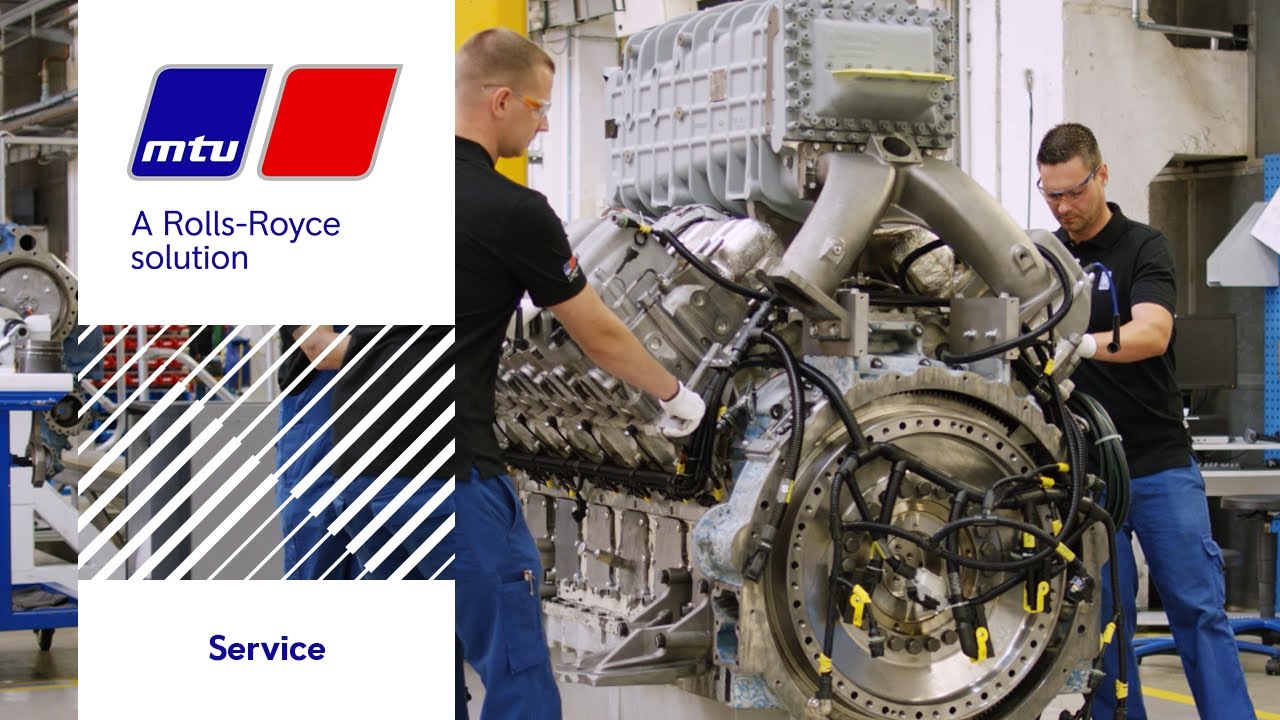

Provided by the same experts who built your original engine or system, mtu Factory Reman and Overhaul Solutions return your equipment to like-new condition—delivering the same high standards of performance, sevice life and quality as comparable new mtu products. And for added confidence, we provide fixed pricing and turnaround times up front and back your restored mtu equipment wih a full factoy waranty.

Factory Reman and Overhaul Solutions deliver the same high standards of performance and support thanks to our rigorous restoration process. While the decision to undergo a reman or overhaul will be determined by your mtu engine series, engine type and supporting mtu service expert, each solution delivers unique benefits based on your engine series and original production date.

Remanufacturing & Overhaul Solutions Marine

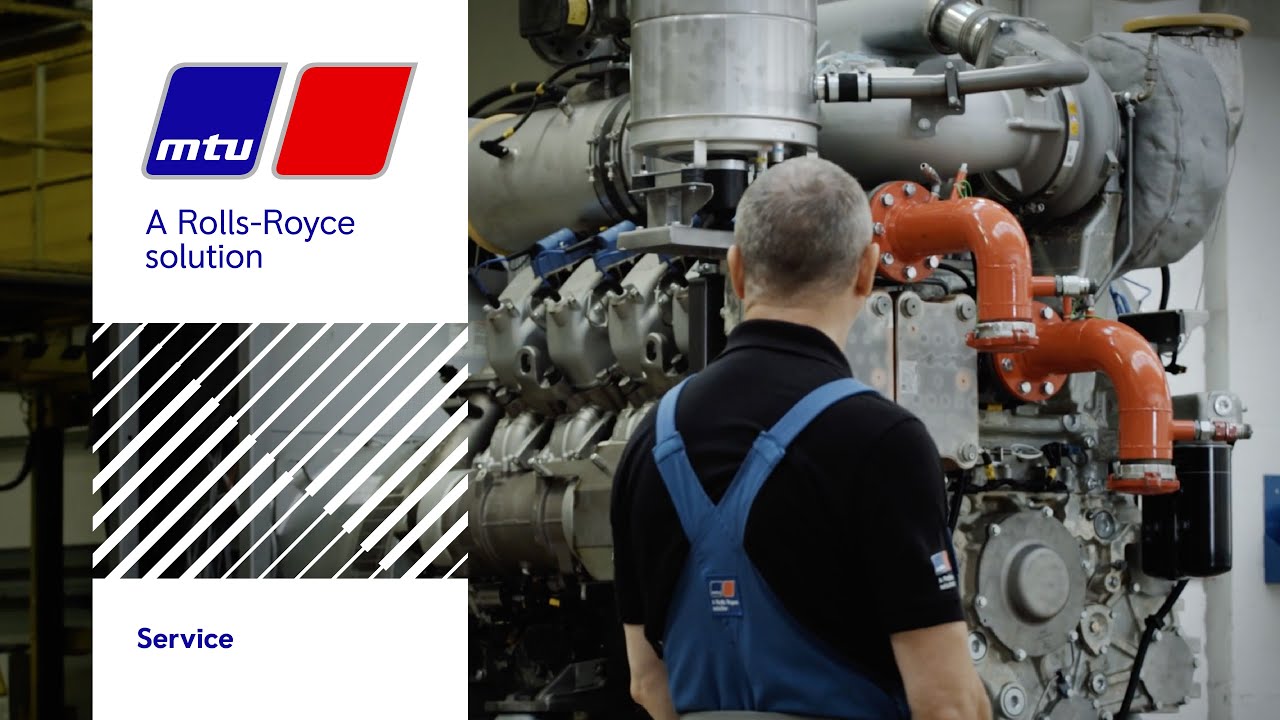

Whether ferries, tugs or any other vessel type: downtimes should be kept as short as possible. With our reliable engines, which are already installed in many ships, we ensure this. But even when the engine is nearing the end of its lifecycle, that doesn’t mean it’s over: We support customers throughout the entire lifecycle and, at the end of it, give the engine a second or even third chance for use with our overhaul solutions.

Find out from our experts in the video what is behind our portfolio.

Factory Reman Solutions

Factory Overhaul Solutions

In-situ Overhaul Solutions

In addition to factory based overhauls, we also offer in-situ overhaul solutions directly inside the ship - saving time and costs while benefitting the environment. Our in-situ overhaul solutions are ideally when circumstances do not allow to remove the engine from the vessel.

With our in-situ options, customers can choose between a comprehensive standard overhaul or a more basic, condition based service.

Making Maintenance Wait: The Extension Of Time Between Overhauls

The Lake Constance ferry Lodi is one of the first vessels to benefit from one of our latest solutions: Extending the time between major overhauls. This extension not only reduces emissions, but also reduces downtime and saves costs over the entire lifecycle of the engine. Watch the video to see how ships can benefit.

Related Content

Here you will find more videos on customized services tailored to your specific needs.

Your benefits through our deposit system

A deposit is included in the price of all our engines. This creates incentives for customers to return the engines to us at the end of their life cycle so that we can recondition them. With our specially designed deposit return system, this process is as easy as can be for customers!

A new engine - from old, completely overhauled parts

In this video, learn how we remanufacture old parts to the highest quality standards and reuse them flexibly to achieve the shortest turnaround times and best results while overhauling engines.

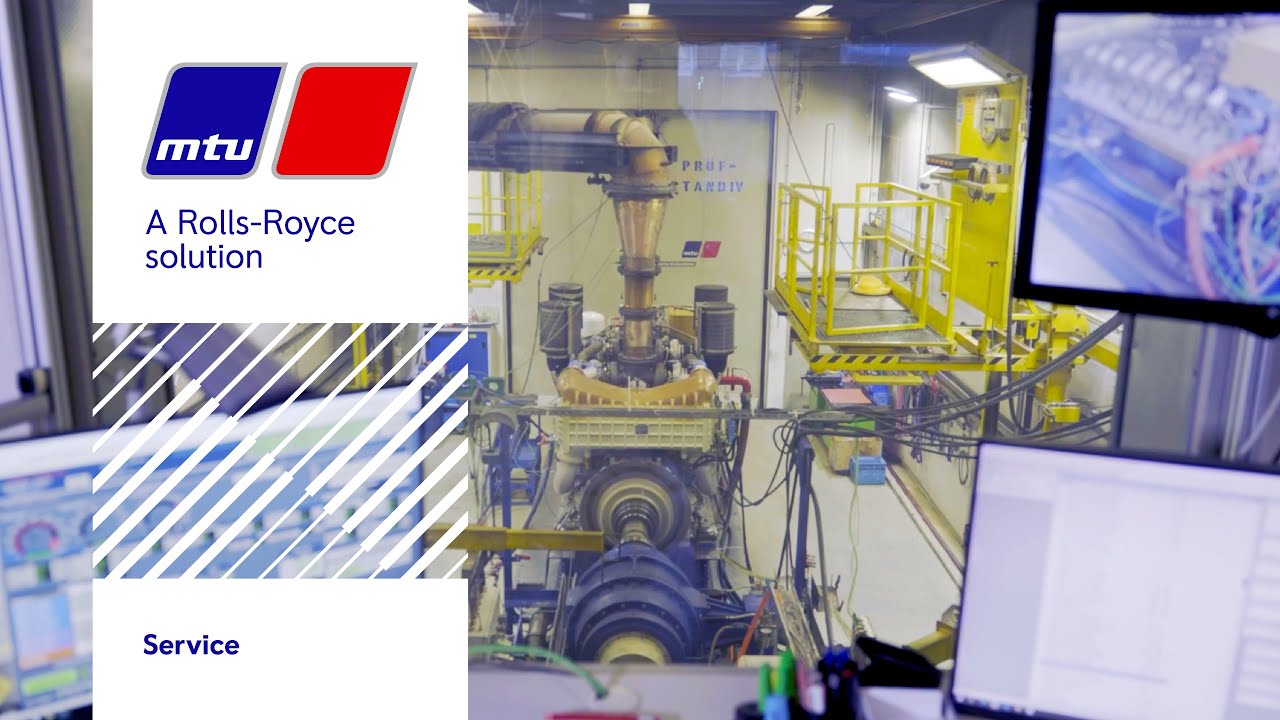

The key to best practices: Our test benches

Our best practices for optimum maintenance and overhaul results are based on industrially repeatable procedures. The standers for these procedures are set in Magdeburg, Germany, and are subsequently used for the overhaul of all our engines worldwide.

Connect with Us