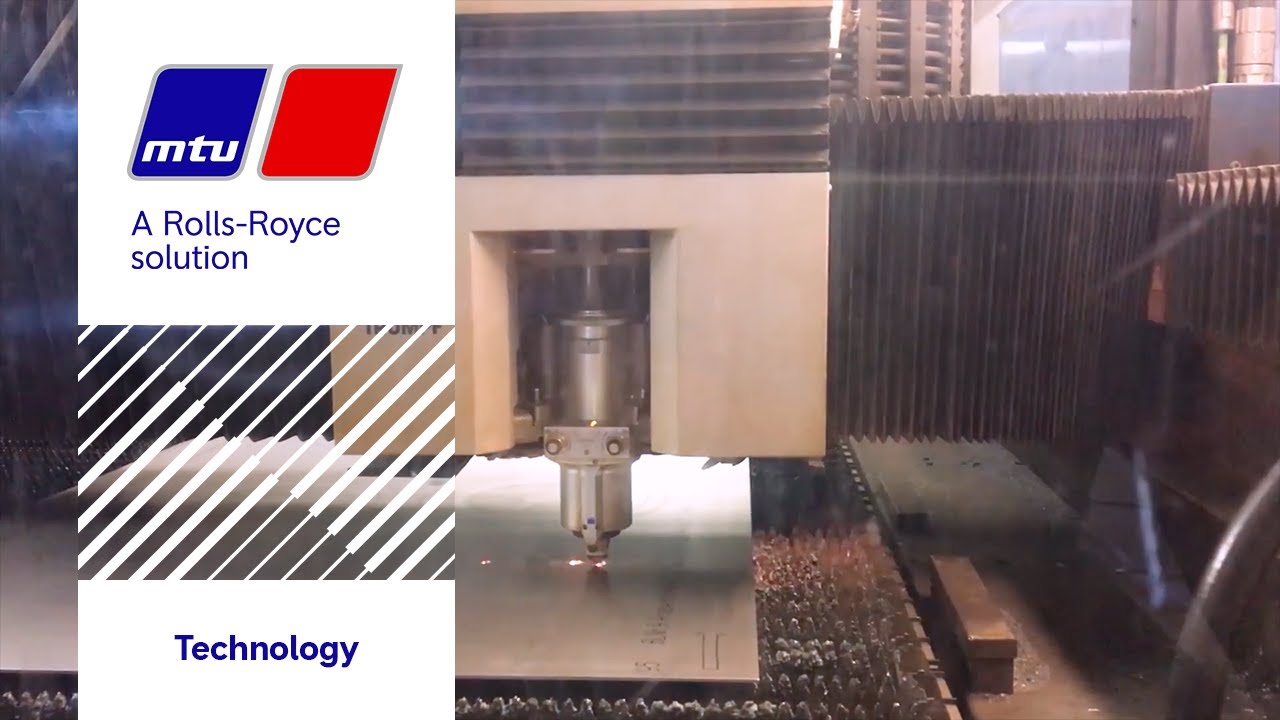

The laser travels in jerky movements across the sheet metal at speeds of over 100 meters per minute. Whatever shape is being cut out – rounded or with corners – the sparks fly, and the cutter moves on to the next piece. When it has finished, the sheet looks like a piece of dough after lots of differently shaped cookies have been cut out.

Around 180,000 components made from 22 different materials are cut out each year by the CO2 laser in mtu's Plant 2 in Friedrichshafen. The 7 kW laser is able to cut almost any material – at mtu, this is mainly carbon steel, nickelchromium steel and aluminum. “It is also able to cut greater sheet thicknesses than many other lasers. As we have to cut a very wide variety of thicknesses, mtu decided on a CO2 laser,” explains Werner Mogicato, Production Planner for welded sheet metals. The CO2 laser can cut carbon steel up to 25 mm thick, nickelchromium steel up to 30mm and aluminum up to 20mm.