What happens when the primary power source fails?

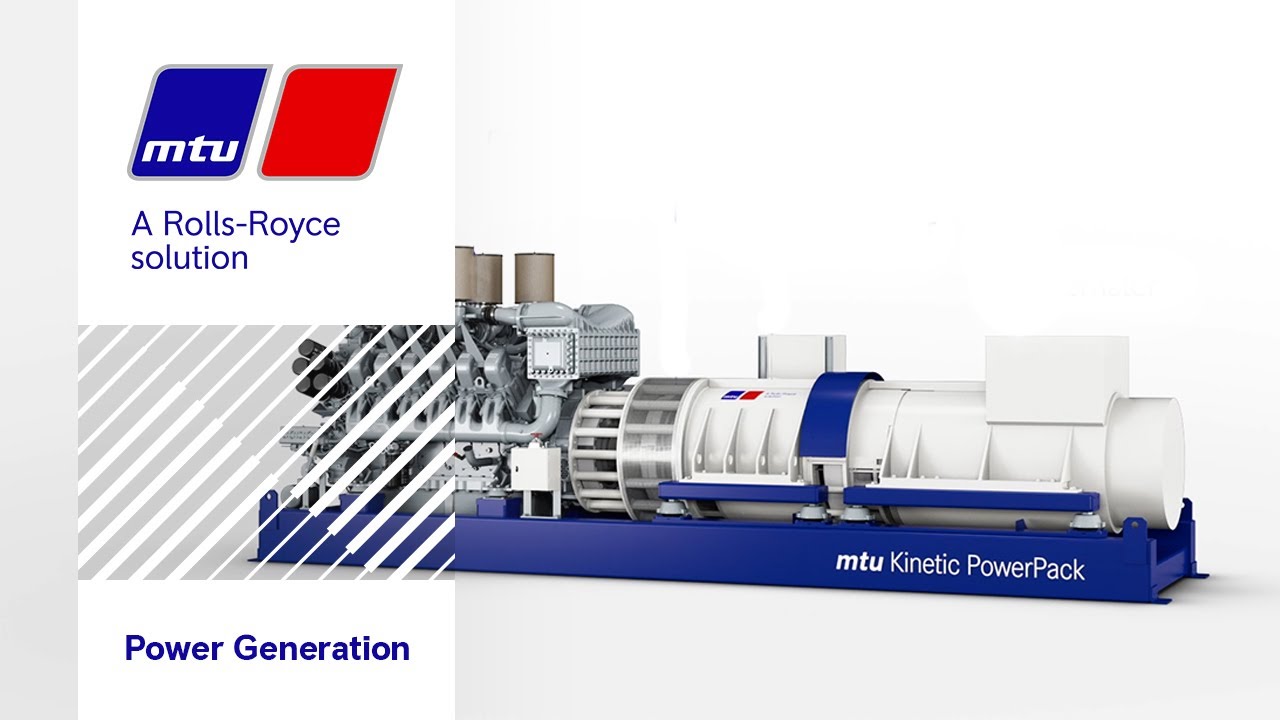

If the public power grid fails, the mtu Kinetic PowerPack acts immediately and without interruption because it is already in operation anyway. Part of the energy stored in the flywheel is used to drive the generator, that starts producing electrical power. Meanwhile, another part of the stored rotational energy is used to facilitate very fast start-up of the diesel engine. Within the shortest possible time the engine accelerates to its rated power output and can now start producing electrical power via the generator and stabilize the flywheel. This naturally happens without any gap or interruption – hence the name 'Uninterruptible Power Supply'.

Is another battery required?

No. With mtu Kinetic PowerPacks, no battery is required. Previously, Rolls-Royce only had mtu standby generator sets in its portfolio for dealing with power outages. These require a certain amount of time to get going, however. To bridge that gap and ensure an uninterrupted flow of power, customers have often resorted to batteries. In mtu Kinetic PowerPacks, however, no such battery is needed, since the energy in the kinetic energy storage unit can be made available immediately for generating power until the mtu diesel engine comes on-line.

What happens precisely?

Well - here's an explanation for the expert or anyone wishing to become one: The flywheel – essentially a kinetic energy accumulator – forms the heart of the system. The flywheel consists of two rotating elements: an outer rotor running freely around an inner rotor which is driven by the main shaft and rotates at 1,500 rpm (50 Hz) or 1,800 rpm (60 Hz). It has two sets of windings: a three-phase alternating current (AC) winding and a direct current (DC) winding.When the public power grid is available, the AC winding is energized to create a rotating magnetic field that drives the outer rotor at a maximum speed of 3,000 rpm. However, the relative speed between the inner and outer rings of the bearings is only 1,500 rpm, since the shaft itself rotates at 1,500 rpm. The external rotor stores kinetic energy advantageously, since the amount of kinetic energy increases by the square as the distance from the center of rotation increases.